Komatsu Avance Loader WA700-3 Shop Manual SEBM013314 – PDF DOWNLOAD

FILE DETAILS:

Komatsu Avance Loader WA700-3 Shop Manual SEBM013314 – PDF DOWNLOAD

Language : English

Pages : 1378

Downloadable : Yes

File Type : PDF

Size: 53.5 MB

DESCRIPTION:

Komatsu Avance Loader WA700-3 Shop Manual SEBM013314 – PDF DOWNLOAD

Machine model Serial number

WA700-3 50001 and up

WA700-3D 50001 and up

GENERAL PRECAUTIONS:

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.

PREPARATIONS FOR WORK:

- 7. Before adding oil or making any repairs, park the machine on hard, level ground, and block the wheels or tracks to prevent the machine from moving.

- 8. Before starting work, lower blade, ripper, bucket or any other work equipment to the ground. If this is not possible, insert the safety pin or use blocks to prevent the work equipment from falling. In addition, be sure to lock all the control levers and hang warning signs on them.

- 9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting work.

- 10.Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine. Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

FOREWORD

GENERAL

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an

accurate understanding of the product and by showing him the correct way to perform repairs and make judgements.

Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service

workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further

divided into the each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding

of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance

standards.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to

be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each component,

as well as precautions for them.

MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts.

The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams.

In addition, this section may give the specifications of attachments and options together.

VIDEO PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Komatsu Avance Loader WA700-3 Shop Manual SEBM013314 – PDF DOWNLOAD

COVER 1

CONTENTS 2

01 GENERAL 31

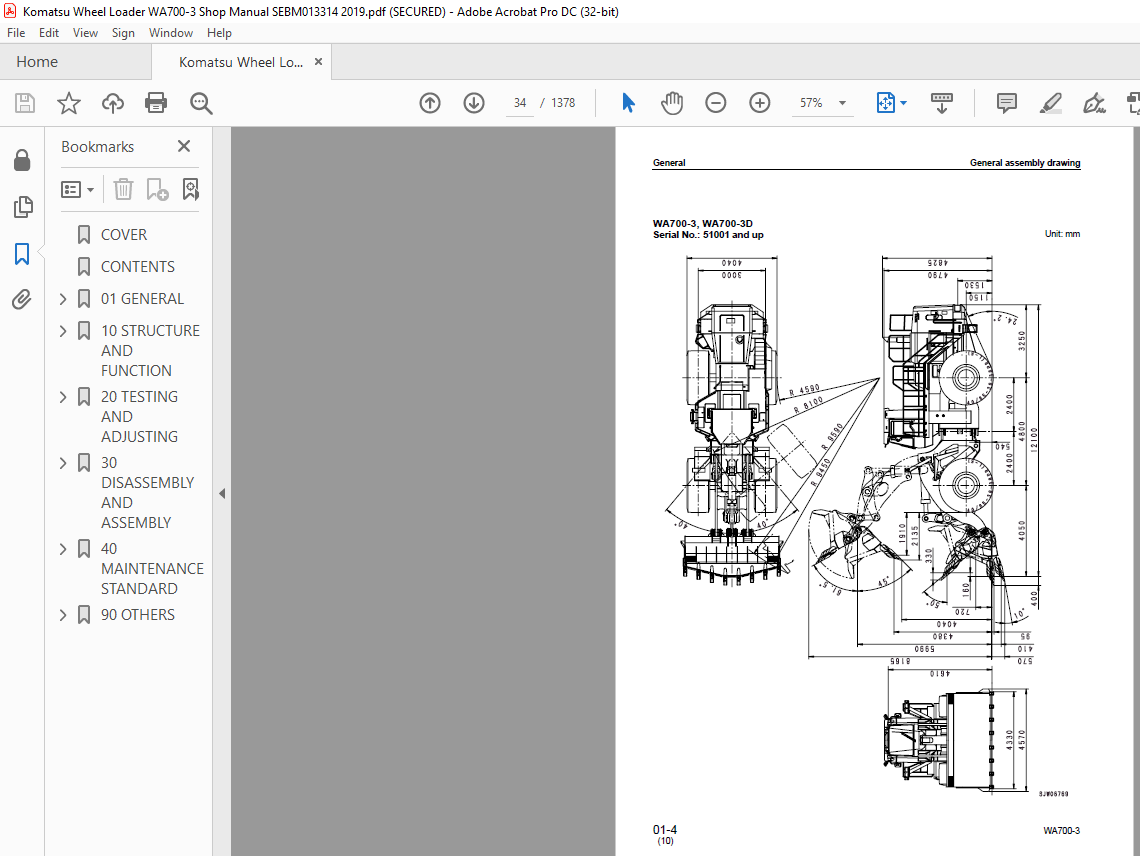

GENERAL ASSEMBLY DRAWING 32

SPECIFICATIONS 35

WEIGHT TABLE 38

LIST OF LUBRICANT AND WATER 40

10 STRUCTURE AND FUNCTION 43

OUTLINE 44

POWER TRAIN SYSTEM 46

DAMPER 48

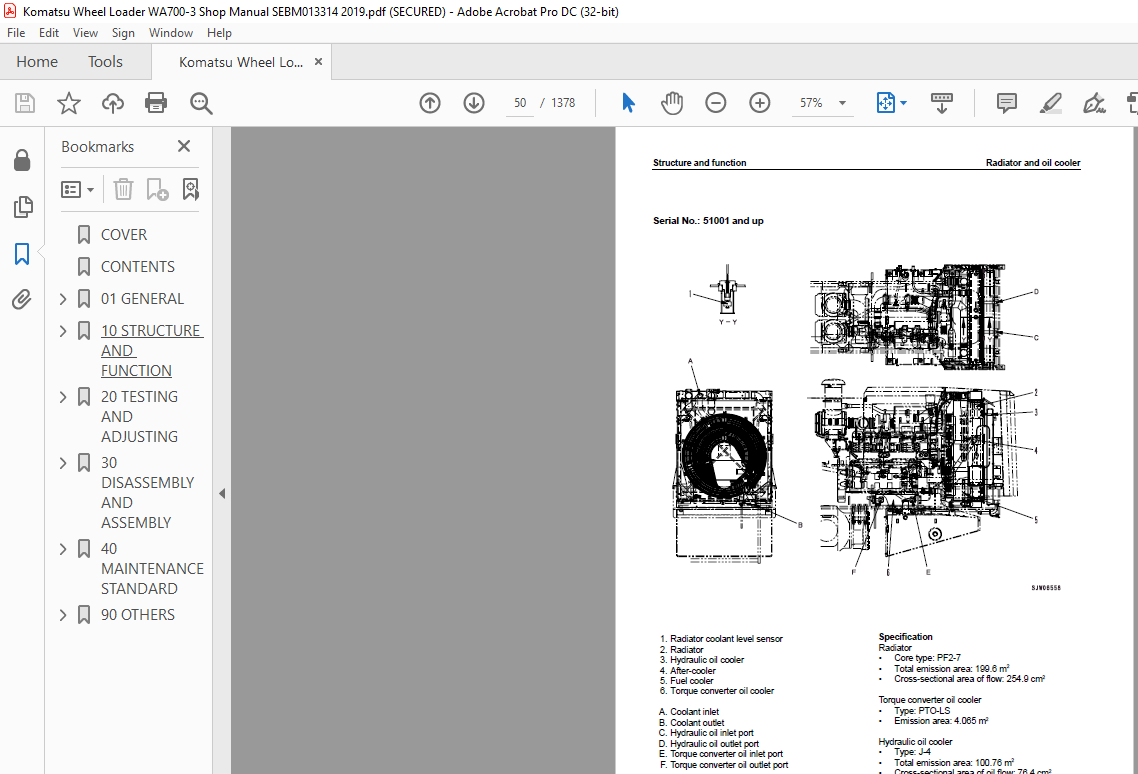

RADIATOR AND OIL COOLER 49

TRANSMISSION HYDRAULIC SYSTEM DIAGRAM 52

TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM 56

TORQUE CONVERTER AND TRANSMISSION PIPING 58

TORQUE CONVERTER AND PTO 60

TORQUE CONVERTER REGULATOR VALVE 67

TRANSMISSION 68

TRANSMISSION CONTROL VALVE 78

TORQUE CONVERTER OIL COOLER 102

TRANSMISSION OIL FILTER 103

TRANSFER 105

AXLE 106

DIFFERENTIAL 108

FINAL DRIVE 110

STEERING PIPING DIAGRAM 113

STEERING AND SWITCH PUMP 114

STEERING UNIT (ORBIT-ROLL VALVE) 118

STEERING DEMAND VALVE 121

TWO-WAY RESTRICTOR VALVE 132

STOP VALVE 133

DIVERTER VALVE 134

BRAKE PIPING 138

BRAKE CIRCUIT DIAGRAM 139

BRAKE VALVE 140

CHARGE VALVE 146

ACCUMULATOR (FOR BRAKE) 150

SLACK ADJUSTER 151

BRAKE 154

PARKING BRAKE 157

SPRING CYLINDER 161

PARKING BRAKE SOLENOID VALVE 162

HYDRAULIC PIPING 164

HYDRAULIC CIRCUIT DIAGRAM 166

MAIN PISTON PUMP 169

ES VALVE (ENGINE SENSING VALVE) 181

SERVO VALVE 182

PRESSURE DIFFERENTIAL VALVE 183

PPC VALVE (PROPORTIONAL PRESSURE VALVE) 184

PPC RELIEF VALVE 188

ACCUMULATOR (FOR PPC VALVE) 189

MAIN CONTROL VALVE 190

LUBRICATION OF WORK EQUIPMENT 214

WORK EQUIPMENT LINKAGE 216

BUCKET POSITIONER AND BOOM KICK-OUT 218

OPERATION OF PROXIMITY SWITCH 220

AIR CONDITIONER 224

ELECTRIC CIRCUIT DIAGRAM 228

MACHINE MONITOR SYSTEM 228

MAIN MONITOR 229

MAINTENANCE MONITOR 233

AUTOMATIC TRANSMISSION SYSTEM (ATM) 235

JOYSTICK STEERING SYSTEM 248

AJSS (ADVANCED JOYSTICK STEERING SYSTEM) 250

TRANSMISSION AND JOYSTICK CONTROLLER 254

ENGINE STARTING CIRCUIT 257

ENGINE STOP CIRCUIT 260

AUTO PRIMING SYSTEM (APS) 262

PREHEATING CIRCUIT 266

FUEL SYSTEM 267

ELECTRICAL TRANSMISSION CONTROL 268

KICK-DOWN, HOLD SWITCH 271

KICK-DOWN ELECTRICAL CIRCUIT 272

ELECTRIC PARKING BRAKE CONTROL 278

ELECTRIC CIRCUIT DIAGRAM OF ACTIVE POWER MAXIMIZING SYSTEM 287

VHMS CONTROLLER 293

BLOW-BY PRESSURE SENSOR 293

ENGINE OIL TEMPERATURE SENSOR 294

EXHAUST TEMPERATURE SENSOR/AMP 295

AMBIENT TEMPERATURE SENSOR 295

TRANSMISSION PUMP OIL PRESSURE SENSOR 296

BRAKE OIL TEMPERATURE SENSOR 297

HYDRAULIC OIL TEMPERATURE SENSOR 297

BRAKE OIL PRESSURE SENSOR 298

STEERING OIL PRESSURE SENSOR 298

WORK EQUIPMENT PUMP OIL PRESSURE SENSOR 298

COMMUNICATIONS (ORB: ORBCOMM) CONTROLLER/ANTENNA 299

20 TESTING AND ADJUSTING 301

STANDARD VALUE TABLE FOR ENGINE 302

STANDARD VALUE TABLE FOR CHASSIS 304

STANDARD VALUE TABLE FOR ELECTRICAL PARTS 311

TESTING AND ADJUSTING 329

TABLE OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING 330

ADJUSTING VALVE CLEARANCE 335

TESTING AND ADJUSTING INJECTOR LIFT 337

MEASURING COMPRESSION PRESSURE 339

MEASURING BLOW-BY PRESSURE 342

TESTING AND ADJUSTING FUEL INJECTION TIMING 343

MEASURING EXHAUST GAS COLOR 345

TESTING AND ADJUSTING ALTERNATOR BELT TENSION 346

TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION 347

HANDLING EQUIPMENT IN FUEL CIRCUIT 348

MEASURING FUEL PUMP OUTLET PORT PRESSURE 348

BLEEDING AIR FROM FUEL CIRCUIT 349

MEASURING EXHAUST TEMPERATURE 351

MEASURING EXHAUST TEMPERATURE (OVERALL ENGINE) 352

MEASURING EXHAUST GAS TEMPERATURE (EACH CYLINDER) 353

MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE) 354

MEASURING ACCELERATOR PEDAL 355

ADJUSTING ACCELERATOR PEDAL TRAVEL, POTENTIOMETER 356

ADJUSTING ACCELERATOR PEDAL MICRO SWITCH 358

MEASURING TORQUE CONVERTER, TRANSMISSION OIL PRESSURE 359

METHOD FOR OPERATION OF EMERGENCY MANUAL SPOOL 361

TESTING AND ADJUSTING STEERING OIL PRESSURE 363

ADJUSTING STEERING STOPPER BOLT 364

ADJUSTING JOYSTICK STEERING 365

ADJUSTING JOYSTICK LEVER NEUTRAL DETECTION SWITCH 367

TESTING BRAKE OIL PRESSURE 368

MEASURING WEAR OF BRAKE DISC 369

MEASURING BRAKE PERFORMANCE 370

TESTING AND ADJUSTING PARKING BRAKE 371

TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE 373

TESTING OF ACCUMULATOR NITROGEN GAS PRESSURE AND PROCEDURE FOR CHARGING ACCUMULATOR WITH NITROGEN GAS 374

MEASURING PPC RELIEF VALVE HYDRAULIC PRESSURE 386

TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE 388

BLEEDING AIR FROM PISTON PUMP 390

ADJUSTING WORK EQUIPMENT LEVER LINKAGE 391

TESTING AND ADJUSTING BUCKET POSITIONER 393

TESTING AND ADJUSTING BOOM KICK-OUT 394

TESTING PROXIMITY SWITCH ACTUATION PILOT LAMP 395

ADJUSTING MAIN MONITOR (SPEEDOMETER MODULE) 396

BLEEDING AIR 397

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT 398

BASIC PRECAUTIONS 399

OUTLINE 402

SETTING UP VHMS CONTROLLER 408

COLLECTION, TRANSMISSION OF DATA 410

INSPECTION AND MAINTENANCE 415

REPLACING PARTS 415

TROUBLESHOOTING 417

POINTS TO REMEMBER WHEN TROUBLESHOOTING 418

SEQUENCE OF EVENTS IN TROUBLESHOOTING 419

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE 420

CHECKS BEFORE TROUBLESHOOTING 428

CONNECTOR TYPES AND MOUNTING LOCATIONS 430

CONNECTOR ARRANGEMENT DIAGRAM 436

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS 447

ELECTRIC ENGINE THROTTLE CONTROLLER SYSTEM 470

METHOD OF DISPLAYING ACTION CODE AND FAILURE CODE 473

CHART OF ACTION CODES AND FAILURE CODES, AND RE-ENACTION 475

TRANSMISSION CONTROLLER LED DISPLAY 477

METHOD OF USING TROUBLESHOOTING CHARTS 478

TROUBLESHOOTING OF ENGINE BODY (S MODE) 481

METHOD OF USING TROUBLESHOOTING CHARTS 482

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME) 486

S-2 ENGINE DOES NOT START 488

a) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT 488

b) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START 489

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR) 490

S-4 ENGINE STOPS DURING OPERATIONS 492

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING) 494

S-6 ENGINE LACKS OUTPUT (OR LACKS POWER) 495

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION) 496

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE) 497

S-9 OIL BECOMES CONTAMINATED QUICKLY 498

S-10 FUEL CONSUMPTION IS EXCESSIVE 499

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN 500

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE) 501

S-13 OIL LEVEL RISES 502

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING) 503

S-15 ABNORMAL NOISE IS MADE 504

S-16 VIBRATION IS EXCESSIVE 506

TROUBLESHOOTING OF MAIN MONITOR SYSTEM (M MODE) 507

ELECTRICAL CIRCUIT DIAGRAM FOR M MODE SYSTEM 510

M-1 MAIN MONITOR DOES NOT WORK 514

M-2 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED IMMEDIATELY, ALL LAMPS STAY LIGHTED UP 515

M-3 SPEEDOMETER DISPLAY DOES NOT WORK PROPERLY 516

M-4 ABNORMALITY IN SHIFT INDICATOR 517

a) DISPLAYS N EVEN WHEN DIRECTIONAL LEVER IS AT F 517

b) DISPLAYS N EVEN WHEN DIRECTIONAL LEVER IS AT R 517

c) DOES NOT DISPLAY N EVEN WHEN DIRECTIONAL LEVER IS AT N, AND DISPLAYS E WHEN DIRECTIONAL LEVER IS AT F 517

d) DOES NOT DISPLAY N EVEN WHEN DIRECTIONAL LEVER IS AT N, AND DISPLAYS E WHEN DIRECTIONAL LEVER IS AT R 518

e) DOES NOT DISPLAY 1ST EVEN WHEN SPEED LEVER IS AT 1 (DIRECTIONAL LEVER AT F OR R) 518

f) DOES NOT DISPLAY 2ND EVEN WHEN SPEED LEVER IS AT 2 (DIRECTIONAL LEVER AT F OR R) 518

g) DOES NOT DISPLAY 3RD EVEN WHEN SPEED LEVER IS AT 3 (DIRECTIONAL LEVER AT F OR R) 519

h) DOES NOT DISPLAY 4TH EVEN WHEN SPEED LEVER IS AT 4 (DIRECTIONAL LEVER AT F OR R) 519

M-5 TURN SIGNAL DISPLAY DOES NOT LIGHT UP 521

a) L H TURN SIGNAL DISPLAY DOES NOT LIGHT UP 521

b) R H TURN SIGNAL DISPLAY DOES NOT LIGHT UP 521

M-6 ABNORMALITY IN PARKING DISPLAY 522

a) PARKING LAMP DISPLAY DOES NOT LIGHT UP 522

b) PARKING LAMP DISPLAY STAYS LIGHTED UP 522

M-7 NIGHT LIGHTING DOES NOT LIGHT UP 523

M-8 ABNORMALITY IN FRONT WORKING LAMP 524

a) NEITHER MONITOR DISPLAY NOR FRONT WORKING LAMP LIGHT UP 524

b) WORKING LAMP LIGHTS UP BUT MONITOR DISPLAY DOES NOT LIGHT UP 524

c) MONITOR DISPLAY LIGHTS UP BUT WORKING LAMP DOES NOT LIGHT UP 524

M-9 ABNORMALITY IN REAR WORKING LAMP 526

a) NEITHER MONITOR DISPLAY NOR REAR WORKING LAMP LIGHT UP 526

b) WORKING LAMP LIGHTS UP BUT MONITOR DISPLAY DOES NOT LIGHT UP 526

c) MONITOR DISPLAY LIGHTS UP BUT WORKING LAMP DOES NOT LIGHT UP 526

M-10 ABNORMALITY IN TRANSMISSION CUT-OFF 528

STANDARD SPECIFICATION 528

a) WHEN TRANSMISSION CUT-OFF SWITCH IS PRESSED, CUT-OFF FUNCTION IS NOT SWITCHED AND DISPLAY DOES NOT CHANGE 528

b) WHEN TRANSMISSION CUT-OFF SWITCH IS TURNED OFF, CUT-OFF FUNCTION IS ALWAYS ACTUATED 528

c) TRANSMISSION CUT-OFF SWITCH TURNED ON, BUT CUT-OFF FUNCTION IS NOT ACTUATED 529

AUTO-SHIFT SPECIFICATION 530

a) WHEN MONITOR SWITCH (TRANSMISSION CUT-OFF SWITCH) IS PRESSED, CUT-OFF FUNCTION IS NOT SWITCHED AND DISPLAY DOES NOT CHANGE 5 530

b) WHEN MONITOR SWITCH (TRANSMISSION CUT-OFF SWITCH) IS OFF, MONITOR DISPLAY GOES OUT BUT CUT-OFF FUNCTION IS ACTUATED WHEN PEDAL IS DEPRESSED 530

c) WHEN MONITOR DISPLAY IS TURNED OFF (TRANSMISSION CUT-OFF SWITCH TURNED OFF), CUT-OFF FUNCTION IS ALWAYS ACTUATED 530

d) CUT-OFF FUNCTION IS ALWAYS ACTUATED REGARDLESS OF MONITOR DISPLAY (TRANSMISSION CUT-OFF SWITCH ON OR OFF) 530

e) MONITOR DISPLAY LIGHTS UP (TRANSMISSION CUT-OFF SWITCH TURNED ON), BUT CUT-OFF FUNCTION IS NOT ACTUATED 531

M-11 ABNORMALITY IN PARKING BRAKE DRAGGING WARNING 532

a) WHEN PARKING BRAKE IS APPLIED, BUZZER SOUNDS (INTERMITTENTLY) AND CAUTION LAMP FLASHES EVEN WHEN DIRECTIONAL LEVER IS AT N 532

b) WHEN PARKING BRAKE IS APPLIED, BUZZER DOES NOT SOUND AND CAUTION LAMP DOES NOT LIGHT UP EVEN WHEN DIRECTIONAL LEVER IS AT POSITION OTHER THAN N 532

M-12 WHEN PARKING BRAKE DRAGGING WARNING IS GIVEN, BUZZER AND CAUTION LAMP ARE ACTUATED CONTINUOUSLY, OR THEY ARE NOT ACTUATED 534

a) ACTUATED CONTINUOUSLY 534

b) NOT ACTUATED 534

M-13 ABNORMALITY IN BUZZER 535

a) BUZZER DOES NOT SOUND WHEN STARTING SWITCH IS AT ON (FOR 3 SECONDS) (DURING SELF-CHECK) 535

b) BUZZER ALWAYS SOUNDS 535

M-14 CONDITION OF MONITOR SWITCHES IS NOT STORED IN MEMORY 536

M-15 ABNORMALITY IN FAILURE DISPLAY MODE 537

a) DOES NOT ENTER FAILURE DISPLAY MODE 537

b) COUNT FOR TIME ELAPSED SINCE FAILURE IN FAILURE DISPLAY MODE DOES NOT ADVANCE 537

M-16 ABNORMALITY IN ELECTRIC ENGINE THROTTLE CONTROLLER ERROR DISPLAY 538

a) THERE IS NO ABNORMALITY ON MACHINE BUT ERROR CODE [91] IS DISPLAYED 538

b) THERE IS NO ABNORMALITY ON MACHINE BUT ERROR CODE [92] IS DISPLAYED 538

c) PROBLEM IS ERROR CODE [90(94)] BUT ERROR CODE [91(93)] IS DISPLAYED 538

d) PROBLEM IS ERROR CODE [90(96)] BUT ERROR CODE [92(95)] IS DISPLAYED 539

M-17 ABNORMALITY IN EMERGENCY STEERING ACTUATION DISPLAY 540

a) EMERGENCY STEERING ACTUATION DISPLAY DOES NOT LIGHT UP 540

b) EMERGENCY STEERING ACTUATION DISPLAY STAYS LIGHTED UP 540

M-18 ABNORMALITY IN AUTO-GREASING SYSTEM 541

a) CHECK POWER SUPPLY SYSTEM 1 (RELAY G1) 541

b) CHECK POWER SUPPLY SYSTEM 2 (RELAY G2) 541

c) FORCED GREASING DOES NOT START 542

d) MONITOR DOES NOT FLASH WHILE GREASE IS BEING SUPPLIED 542

e) MONITOR IS STILL FLASHING AFTER GREASING IS FINISHED, OR IT FLASHES FOR PERIOD SET WITH TIMER WHEN STARTING SWITCH IS TURNED TO ON POSITION 543

M-19 ABNORMALITY IN LOW IDLING SELECT SYSTEM 545

a) DISPLAY DOES NOT CHANGE WHEN SWITCH IS PRESSED (SERIAL NO : 50001 – 51000) 545

b) MONITOR DISPLAY LIGHTS UP BUT LOW IDLING SELECT FUNCTION DOES NOT WORK (SERIAL NO : 50001 – 51000) 545

a) DISPLAY DOES NOT CHANGE WHEN SWITCH IS PRESSED (SERIAL NO : 51001 AND UP) 546

b) MONITOR DISPLAY LIGHTS UP BUT LOW IDLING SELECT FUNCTION DOES NOT WORK (SERIAL NO : 51001 AND UP) 546

TROUBLESHOOTING OF MAINTENANCE MONITOR SYSTEM (K MODE) 547

ELECTRICAL CIRCUIT DIAGRAM FOR K MODE SYSTEM 548

K-1 WHEN STARTING SWITCH IS TURNED ON, ALL LAMPS ON MAINTENANCE MONITOR DO NOT LIGHT UP FOR 3 SECONDS, MAINTENANCE MONITOR DOES NOT WORK 550

a) NO LAMPS ON MAINTENANCE MONITOR LIGHT UP 550

b) SOME LAMPS DO NOT LIGHT UP 550

K-2 WHEN STARTING SWITCH IS TURNED ON, ALL LAMPS ON MAINTENANCE MONITOR LIGHT UP BUT DO NOT GO OUT (EVEN AFTER 3 SECONDS) 551

K-3 WHEN ENGINE IS STARTED IMMEDIATELY AFTER STARTING SWITCH IS TURNED ON (WITHIN 3 SECONDS), NO LAMPS ON MAINTENANCE MONITOR GO OUT 552

K-4 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CHECK ITEMS FLASH 553

a) ENGINE OIL LEVEL DISPLAY FLASHES 553

b) ENGINE WATER LEVEL DISPLAY FLASHES (SERIAL NO : 50001 – 51000) 554

b) ENGINE WATER LEVEL DISPLAY FLASHES (SERIAL NO : 51001 AND UP) 555

K-5 WHEN STARTING SWITCH IS TURNED ON (ENGINE STARTED), CAUTION ITEMS FLASH 556

a) ENGINE OIL PRESSURE DISPLAY FLASHES (CHECK THAT THE ENGINE OIL PRESSURE IS CORRECT ) (SERIAL NO : 50001 – 51000) 556

a) ENGINE OIL PRESSURE DISPLAY FLASHES (CHECK THAT THE ENGINE OIL PRESSURE IS CORRECT ) (SERIAL NO : 51001 AND UP) 557

b) BATTERY CHARGE LEVEL DISPLAY FLASHES 558

c) BRAKE OIL PRESSURE DISPLAY FLASHES (CHECK THAT THE BRAKE OIL PRESSURE IS CORRECT ) 559

d) AIR CLEANER (L H ) DISPLAY FLASHES 560

e) AIR CLEANER (R H ) DISPLAY FLASHES 561

f) AIR CLEANER DISPLAY FLASHES 562

K-6 CAUTION ITEMS ARE FLASHING BUT CAUTION BUZZER DOES NOT SOUND 563

K-7 THERE IS NO ABNORMALITY IN MONITOR DISPLAY BUT CAUTION BUZZER SOUNDS 564

K-8 CAUTION ITEMS ARE FLASHING BUT WARNING LAMP (CHECK LAMP, CAUTION LAMP) DOES NOT FLASH 565

a) CHECK LAMP 565

b) CAUTION LAMP 565

K-9 THERE IS NO ABNORMALITY IN MAINTENANCE MONITOR DISPLAY BUT WARNING LAMP (CHECK LAMP, CAUTION LAMP) LIGHTS UP 566

a) CHECK LAMP 566

b) CAUTION LAMP 566

K-10 NIGHT LIGHTING DOES NOT LIGHT UP WHEN LAMP SWITCH IS TURNED ON (ONLY LIGHTING OF MAINTENANCE MONITOR DOES NOT LIGHT UP) 567

K-11 NIGHT LIGHTING LIGHTS UP EVEN WHEN LAMP SWITCH IS OFF, NIGHT LIGHTING STAYS LIGHTED UP 568

K-12 SERVICE METER DOES NOT WORK 569

K-13 SERVICE METER IS RUNNING EVEN WHEN ENGINE IS STOPPED 569

K-14 ABNORMALITY IN GAUGE ITEMS 571

a) ABNORMALITY IN FUEL GAUGE 571

b) ABNORMALITY IN ENGINE WATER TEMPERATURE GAUGE 572

c) ABNORMALITY IN TORQUE CONVERTER OIL TEMPERATURE GAUGE 573

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) 575

ELECTRICAL CIRCUIT DIAGRAM FOR E MODE SYSTEM 578

E-1 ENGINE DOES NOT START 582

a) STARTING MOTOR DOES NOT TURN 582

b) STARTING MOTOR TURNS 588

E-2 ABNORMALITY IN APS SYSTEM 598

a) WHEN PREHEATING SWITCH IS TURNED AUTO, PREHEATING LAMP DOES NOT LIGHT UP, BUT NO PILOT LED ON APS CONTROLLER LIGHTS UP 600

b) WHEN PREHEATING SWITCH IS TURNED AUTO AND ENGINE WATER TEMPERATURE IS BELOW 20ºC, PREHEATING LAMP FLASHES, BUT PILOT LED ON APS CONTROLLER SHOWS NORMAL 601

c) AFTER PREHEATING, FUEL IS NOT INJECTED FROM APS NOZZLE WHEN STARTING SWITCH IS TURNED START, BUT PILOT LED ON APS CONTROLLER SHOWS NORMAL 602

d) LED 1 OF PILOT LED ON APS CONTROLLER SHOWS ABNORMAL 603

e) LED 2 OF PILOT LED ON APS CONTROLLER SHOWS ABNORMAL 603

f) LED 3 OF PILOT LED ON APS CONTROLLER SHOWS ABNORMAL 604

g) LED 4 OF PILOT LED ON APS CONTROLLER SHOWS ABNORMAL 604

h) LED 5 OF PILOT LED ON APS CONTROLLER SHOWS ABNORMAL 605

i) LED 6 OF PILOT LED ON APS CONTROLLER SHOWS ABNORMAL 605

j) WHEN PREHEATING SWITCH IS OFF, PREHEATING LAMP LIGHTS UP 606

E-3 PARKING BRAKE DOES NOT HAVE EFFECT 607

a) PARKING BRAKE HAS NO EFFECT WHEN PARKING BRAKE SWITCH IS TURNED ON 607

b) PARKING BRAKE HAS NO EFFECT AND DOES NOT WORK AS EMERGENCY BRAKE WHEN PARKING BRAKE PRESSURE DROPS 607

E-4 PARKING BRAKE IS APPLIED WHEN MACHINE IS TRAVELING 608

E-5 PARKING BRAKE IS RELEASED WHEN STARTING SWITCH IS TURNED ON 610

E-6 TRANSMISSION DOES NOT CHANGE TO NEUTRAL WHEN PARKING BRAKE IS APPLIED, BUT PARKING BRAKE WORKS NORMALLY 610

E-7 TRANSMISSION DOES NOT WORK PROPERLY 613

a) ABNORMALITY IN PARKING BRAKE CIRCUIT, TRANSMISSION CUT-OFF SWITCH CIRCUIT OR NEUTRALIZER RELAY CIRCUIT 614

b) NO CONTINUITY IN TRAVEL FORWARD SOLENOID CIRCUIT 618

c) NO CONTINUITY IN TRAVEL REVERSE SOLENOID CIRCUIT 620

d) SHORT CIRCUIT TO CHASSIS GROUND IN DIRECTIONAL SOLENOID CIRCUIT 622

e) ABNORMALITY IN SHIFT SOLENOID CIRCUIT 628

f) SHORT CIRCUIT TO CHASSIS GROUND IN SHIFT SOLENOID CIRCUIT 631

E-8 KICK-DOWN SWITCH DOES NOT WORK 636

E-9 KICK-DOWN WORKS ONLY WHEN KICK-DOWN SWITCH IS BEING TURNED ON 639

E-10 KICK-DOWN ALWAYS WORKS 640

E-11 KICK-DOWN SWICH WORKS EVEN WHEN TRAVELING FORWARD IN 2ND 642

E-12 BOOM KICK-OUT DOES NOT WORK 644

E-13 DEFECTIVE BUCKET POSITIONER 646

E-14 POWER WINDOW DOES NOT WORK 648

a) WINDOW DOES NOT GO UP 648

b) WINDOW DOES NOT GO DOWN 649

E-15 ABNORMALITY IN FRONT WORKING LAMP 651

E-16 ABNORMALITY IN REAR WORKING LAMP 651

E-17 ABNORMALITY IN TRANSMISSION CUT-OFF 651

E-18 ABNORMALITY IN PARKING BRAKE DRAGGING WARNING 651

E-19 ABNORMALITY IN BUZZER 651

TROUBLESHOOTING OF ELECTRIC ENGINE THROTTLE CONTROLLER & APS CONTROLLER SYSTEM SYSTEM (G MODE) 653

JUDGEMENT TABLE FOR ENGINE CONTROLLER AND ENGINE RELATED PARTS 654

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ABNORMALITY OCCURS 656

ACTION TAKEN BY CONTROLLER AND CONDITIONS FOR RESETTING WHEN ABNORMALITY OCCURS 662

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM 663

JUDGEMENT TABLE FOR ENGINE CONTROLLER 665

G-1 [90] [OFF OR 10] ABNORMALITY IN POWER SOURCE SYSTEM 666

G-2 [90] [11] ABNORMALITY IN CONTROLLER SYSTEM 666

G-3 [90] [21] MISTAKEN CONNECTION OF CONNECTOR 667

G-4 [90] [56] ABNORMALITY IN CONTROLLER SOLENOID POWER SOURCE SYSTEM 667

G-5 [90] [58] ABNORMALITY IN BACK-UP POWER SOURCE SYSTEM 668

G-6 [90] [59] ABNORMALITY IN SWITCH POWER SOURCE SYSTEM 669

G-7 [91] [14] ABNORMALITY IN GOVERNOR SOLENOID SYSTEM 670

G-8 [91] [16] ABNORMALITY IN GOVERNOR CUT RELAY SYSTEM 671

G-9 [91] [19] ABNORMALITY IN GOVERNOR SERVO SYSTEM 672

G-10 [91] [1D] ABNORMALITY IN PRE-STROKE SOLENOID SYSTEM 673

G-11 [92] [12] ABNORMALITY IN RACK SENSOR SYSTEM 674

G-12 [92] [18] ABNORMALITY IN RACK SENSOR POWER SOURCE SYSTEM 675

G-13 [93] [1B] ABNORMALITY IN ENGINE SPEED SENSOR A SYSTEM 676

G-14 [94] [1C] ABNORMALITY IN ENGINE SPEED SENSOR B SYSTEM 677

G-15 [93,94] [1B, 1C] ABNORMALITY IN ENGINE SPEED SENSOR A, B SYSTEM 678

G-16 [95] [40] ABNORMALITY IN WATER TEMPERATURE SENSOR SYSTEM 678

G-17 [97] [31] ABNORMALITY IN ACCELERATOR SENSOR SYSTEM 679

G-18 [99] [22] ENGINE OVERRUN 681

G-19 ENGINE DOES NOT START (CONTROLLER RELATED ONLY) 681

G-20 ENGINE DOES NOT START 682

G-21 ENGINE DOES NOT STOP 685

G-22 DEFECTIVE ACTUATION OF APS 686

a) PREHEATING LAMP SWITCH DOES NOT LIGHT UP WHEN APS SWITCH IS ON (ALL APS CONTROLLER LEDS ARE ALSO OFF) 686

b) PREHEATING PILOT LAMP FLASHES WHEN WATER TEMPERATURE IS BELOW 20ºC WHEN APS SWITCH IS ON (CONTROLLER LEDS ALL GIVE NORMAL DISPLAY)

PREHEATING PILOT LAMP LIGHTS UP WHEN WATER TEMPERATURE IS ABOVE 20ºC WHEN APS SWITCH IS ON (CONTROLLER LEDS ALL GIVE NORMAL DISPLAY) 688

c) NOZZLE DOES NOT INJECT FUEL WHEN STARTING SWITCH IS TURNED TO START AFTER COMPLETION OF PREHEATING WHEN APS SWITCH IS ON (CONTROLLER LEDS ALL GIVE NORMAL DISPLAY) 688

d) APS CONTROLLER LED 1 (SHORT CIRCUIT IN GLOW PLUG 1 SYSTEM) GIVES ABNORMAL DISPLAY 689

e) APS CONTROLLER LED 2 (DISCONNECTION IN GLOW PLUG 1 SYSTEM) GIVES ABNORMAL DISPLAY 689

f) APS CONTROLLER LED 3 (SHORT CIRCUIT IN GLOW PLUG 2 SYSTEM) GIVES ABNORMAL DISPLAY 690

g) APS CONTROLLER LED 4 (DISCONNECTION IN GLOW PLUG 2 SYSTEM) GIVES ABNORMAL DISPLAY 690

h) APS CONTROLLER LED 5 (SHORT CIRCUIT WITH GROUND IN NOZZLE) GIVES ABNORMAL DISPLAY 691

i) APS CONTROLLER LED 6 (DISCONNECTION IN NOZZLE) GIVES ABNORMAL DISPLAY 691

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE) 693

METHOD OF USING MATRIX TROUBLESHOOTING TABLES 696

H-1 MACHINE DOES NOT START 698

H-2 MACHINE LACKS POWER OR SPEED WHEN TRAVELING (ALL SPEED RANGES) 699

H-3 TIME LAG IS EXCESSIVE WHEN STARTING OR SHIFTING GEAR 700

H-4 TORQUE CONVERTER OIL TEMPERATURE IS HIGH 701

H-5 STEERING DOES NOT TURN (STEERING WHEEL SPECIFICATION) 702

H-6 STEERING DOES NOT TURN (STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 703

H-7 STEERING DOES NOT TURN (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 704

H-8 TURNING, RESPONSE OF STEERING IS POOR (STEERING WHEEL SPECIFICATION) 705

H-9 TURNING, RESPONSE OF STEERING IS POOR (STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 706

H-10 TURNING, RESPONSE OF STEERING IS POOR (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 708

H-11 STEERING IS HEAVY (STEERING WHEEL SPECIFICATION) 709

H-12 JOYSTICK LEVER IS HEAVY (STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 709

H-13 JOYSTICK LEVER IS HEAVY (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 710

H-14 STEERING WHEEL SHAKES OR JERKS (STEERING WHEEL SPECIFICATION) 711

H-15 STEERING SHAKES OR THERE IS EXCESSIVE SHOCK (STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 712

H-16 STEERING WHEEL SHAKES OR JERKS (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 713

H-17 MINIMUM TURNING RADII TO RIGHT AND LEFT ARE DIFFERENT (STEERING WHEEL SPECIFICATION, STEERIG WHEEL AND JOYSTICK STEERING SPECIFICATION) 714

H-18 MINIMUM TURNING RADII TO RIGHT AND LEFT ARE DIFFERENT (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 714

H-19 WHEEL BRAKES DO NOT WORK OR BRAKING EFFECT IS POOR 716

H-20 WHEEL BRAKES ARE NOT RELEASED OR BRAKES DRAG 718

H-21 PARKING BRAKE DOES NOT WORK OR BRAKING EFFECT IS POOR 719

H-22 PARKING BRAKE IS NOT RELEASED OR BRAKE DRAGS 720

H-23 NEITHER BOOM NOR BUCKET MOVE 721

H-24 BOTH BOOM AND BUCKET ARE SLOW OR LACK POWER 722

H-25 BOOM DOES NOT MOVE 723

H-26 BOOM IS SLOW OR BOOM LACKS POWER 724

H-27 BOOM CANNOT BE SET TO FLOAT OR CANNOT BE RELEASED FROM FLOAT 725

H-28 BOOM DROPS MOMENTARILY WHEN CONTROL LEVER IS OPERATED FROM HOLD TO RAISE 725

H-29 EXCESSIVE HYDRAULIC DRIFT OF BOOM 726

H-30 BUCKET DOES NOT MOVE 727

H-31 BUCKET IS SLOW OR LACKS POWER 728

H-32 EXCESSIVE HYDRAULIC DRIFT OF BUCKET 729

TROUBLESHOOTING OF TRANSMISSION CONTROL SYSTEM (T MODE) 731

JUDGEMENT TABLE FOR TRANSMISSION CONTROLLER SYSTEM RELATED PARTS 734

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE 738

ELECTRICAL CIRCUIT DIAGRAM FOR TRANSMISSION CONTROL SYSTEM 748

T-1 FAILURE CODE [10] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN BACKUP LAMP RELAY) IS DISPLAYED 752

T-2 FAILURE CODE [12] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN F SOLENOID) IS DISPLAYED 753

T-3 FAILURE CODE [13] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN R SOLENOID) IS DISPLAYED 754

T-4 FAILURE CODE [14] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 1ST SOLENOID) IS DISPLAYED 755

T-5 FAILURE CODE [15] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 2ND SOLENOID) IS DISPLAYED 756

T-6 FAILURE CODE [16] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 3RD SOLENOID) IS DISPLAYED 757

T-7 FAILURE CODE [17] (SHORT CIRCUIT, DISCONNECTION, SHORT CIRCUIT WITH POWER SOURCE IN 4TH SOLENOID) IS DISPLAYED 758

T-8 FAILURE CODE [19] (SHORT CIRCUIT, DISCONNECTION IN JOYSTICK DIRECTIONAL SWITCH SYSTEM) IS DISPLAYED (STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 759

T-9 FAILURE CODE [20] (SHORT CIRCUIT, DISCONNECTION IN DIRECTIONAL SWITCH SYSTEM) IS DISPLAYED (STEERING WHEEL SPECIFICATION, STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 760

T-10 FAILURE CODE [20] (SHORT CIRCUIT OR DISCONNECTION IN JOYSTICK DIRECTIONAL SWITCH SYSTEM) IS DISPLAYED (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 763

T-11 FAILURE CODE [21] (SHORT CIRCUIT, DISCONNECTION IN RANGE SWITCH SYSTEM) IS DISPLAYED (STEERING WHEEL SPECIFICATION, STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 764

T-12 FAILURE CODE [21] (SHORT CIRCUIT OR DISCONNECTION IN JOYSTICK SHIFT-UP/SHIFT-DOWN SWITCH SYSTEM) IS DISPLAYED (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 768

T-13 FAILURE CODE [22] (DISCONNECTION IN TRAVEL SPEED SENSOR SYSTEM) IS DISPLAYED (STEERING WHEEL SPECIFICATION, STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 770

T-14 FAILURE CODE [22] (DISCONNECTION IN TRAVEL SPEED SENSOR SYSTEM) IS DISPLAYED (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 771

T-15 FAILURE CODE [23] (SHORT CIRCUIT, DISCONNECTION IN ENGINE SPEED SENSOR SYSTEM) IS DISPLAYED 772

a) TRANSMISSION CONTROLLER SYSTEM 772

b) ELECTRIC ENGINE THROTTLE CONTROLLER SYSTEM 772

T-16 KICKDOWN SWITCH SIGNAL SYSTEM AND HOLD SWITCH SIGNAL SYSTEM (STEERING WHEEL SPECIFICATION, AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 776

T-17 SHIFT-DOWN SWITCH SIGNAL SYSTEM AND SHIFT-UP SWITCH SIGNAL SYSTEM (STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 777

T-18 TRANSMISSION CUT-OFF SIGNAL SYSTEM 778

T-19 NEUTRALIZER RELAY SIGNAL SYSTEM (STEERING WHEEL SPECIFICATION, STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 779

T-20 NEUTRALIZER RELAY SIGNAL SYSTEM (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 780

T-21 BUZZER SIGNAL SYSTEM 782

T-22 NETWORK SYSTEM 783

T-23 TRANSMISSION CONTROLLER POWER SOURCE SYSTEM (STEERING WHEEL SPECIFICATION, STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 784

T-24 TRANSMISSION CONTROLLER POWER SOURCE SYSTEM (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 785

T-25 SHORT CIRCUIT IN TRAVEL SPEED SENSOR SYSTEM (STEERING WHEEL SPECIFICATION, STEERING WHEEL AND JOYSTICK STEERING SPECIFICATION) 786

T-26 SHORT CIRCUIT IN TRAVEL SPEED SENSOR SYSTEM (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) 787

TROUBLESHOOTING OF JOYSTICK STEERING CONTROLLER SYSTEM (J MODE) 789

JUDGEMENT TABLE FOR JOYSTICK CONTROLLER SYSTEM RELATED PARTS 790

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE 792

ELECTRICAL CIRCUIT DIAGRAM FOR JOYSTICK STEERING SYSTEM 796

J-1 FAILURE CODE [56] (SHORT CIRCUIT, DISCONNECTION IN CAUTION RELAY OUTPUT) IS DISPLAYED 797

J-2 FAILURE CODE [57] (SHORT CIRCUIT IN STEERING RIGHT SOLENOID (DETECTED WHEN OUTPUT)) IS DISPLAYED 798

J-3 FAILURE CODE [58] (SHORT CIRCUIT IN STEERING LEFT SOLENOID (DETECTED WHEN OUTPUT)) IS DISPLAYED 799

J-4 FAILURE CODE [59] (SHORT CIRCUIT IN STEERING RIGHT SOLENOID (HOT END)) IS DISPLAYED 800

J-5 FAILURE CODE [60] (SHORT CIRCUIT IN STEERING LEFT SOLENOID (HOT END)) IS DISPLAYED 801

J-6 FAILURE CODE [61] (SHORT CIRCUIT, DISCONNECTION IN STEERING SOLENOID CUT RELAY OUTPUT) IS DISPLAYED 802

J-7 FAILURE CODE [62] (SHORT CIRCUIT, DISCONNECTION IN JOYSTICK STEERING NEUTRAL SIGNAL) IS DISPLAYED 803

J-8 FAILURE CODE [63] (SHORT CIRCUIT, DISCONNECTION IN JOYSTICK STEERING LEVER POTENTIOMETER SYSTEM) IS DISPLAYED 804

J-9 ABNORMALITY IN POWER SOURCE, VOLTAGE 805

J-10 ABNORMALITY IN JOYSTICK STEERING ON-OFF SIGNAL SYSTEM 806

J-11 DISCONNECTION IN STEERING RIGHT SOLENOID 807

J-12 DISCONNECTION IN STEERING LEFT SOLENOID 808

TROUBLESHOOTING OF AJSS (ADVANCED JOYSTICK STEERING SYSTEM) CONTROL SYSTEM (A MODE) 809

JUDGEMENT TABLE FOR AJSS (ADVANCED JOYSTICK STEERING SYSTEM) CONTROL SYSTEM 810

OPERATIONS OF CONTROLLER AGAINST ABNORMALITY AND CONDITIONS OF MACHINE CAUSED BY ABNORMALITY 812

ELECTRIC CIRCUIT DIAGRAM RELATED TO AJSS (ADVANCED JOYSTICK STEERING SYSTEM) CONTROL 816

A-1 ERROR CODE [56] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN CAUTION BUZZER RELAY SYSTEM) IS DISPLAYED 818

A-2 ERROR CODE [57] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN STEERING LEVER ANGLE SENSOR SYSTEM) IS DISPLAYED 819

A-3 ERROR CODE [58] (DEVIATION OF STEERING LEVER ANGLE SENSOR AND FRAME ANGLE SENSOR SIGNALS) IS DISPLAYED 820

A-4 ERROR CODE [59] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN FRAME ANGLE SENSOR SYSTEM) IS DISPLAYED 821

A-5 ERROR CODE [60] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN STEERING LEVER LOCK PRESSURE SWITCH SYSTEM) IS DISPLAYED 822

A-6 ERROR CODE [62] (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN STEERING NEUTRAL INTERLOCK RELAY SYSTEM) IS DISPLAYED 823

A-7 ERROR CODE [63] (DISCONNECTION, SHORT CIRCUIT WITH CHASSIS GROUND, OR SHORT CIRCUIT WITH POWER SOURCE IN STEERING MAIN PRESSURE CONTROL EPC SOLENOID SYSTEM) IS DISPLAYED 824

A-8 STEERING SPEEDS IN BOTH DIRECTIONS ARE DIFFERENT 825

A-9 ABNORMALITY IN CONSOLE SWITCH (ADJUSTMENT OF STEERING LEVER ANGLE SENSOR AND FRAME ANGLE SENSOR IS IMPOSSIBLE) 826

A-10 ABNORMALITY IN POWER SOURCE AND VOLTAGE 827

TROUBLESHOOTING OF ENGINE CONTROL SYSTEM (EA MODE) 829

METHOD OF ERROR CODE DISPLAY 831

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED 834

ELECTRICAL CIRCUIT DIAGRAM FOR ENGINE CONTROL SYSTEM 842

EA-1 ERROR CODE [111] (ABNORMALITY IN CONTROLLER MEMORY) 844

EA-2 ERROR CODE [112] (ABNORMALITY IN TIMING RAIL ACTUATOR) 844

EA-3 ERROR CODE [113] (ABNORMALITY WITH ELECTRIC CURRENT IN TIMING RAIL ACTUATOR SYSTEM) 845

EA-4 ERROR CODE [115] (ABNORMALITY IN ENGINE SPEED SENSOR 2 SYSTEM) 846

EA-5 ERROR CODE [116] (ABNORMALITY [HIGH LEVEL] IN TIMING RAIL PRESSURE SENSOR SYSTEM) 848

EA-6 ERROR CODE [117] (ABNORMALITY [LOW LEVEL] IN TIMING RAIL PRESSURE SENSOR SYSTEM) 849

EA-7 ERROR CODE [118] (ABNORMALITY [HIGH LEVEL] IN FUEL PUMP PRESSURE SENSOR SYSTEM) 850

EA-8 ERROR CODE [119] (ABNORMALITY [LOW LEVEL] IN FUEL PUMP PRESSURE SENSOR SYSTEM) 851

EA-9 ERROR CODE [121] (ABNORMALITY IN ENGINE SPEED SENSOR 1 SYSTEM) 852

EA-10 ERROR CODE [122] (ABNORMALITY [HIGH LEVEL] IN BOOST PRESSURE SENSOR SYSTEM) 853

EA-11 ERROR CODE [123] (ABNORMALITY [LOW LEVEL] IN BOOST PRESSURE SENSOR SYSTEM) 854

EA-12 ERROR CODE [131] (ABNORMALITY [HIGH LEVEL] IN ACCELERATOR SENSOR SYSTEM) 855

EA-13 ERROR CODE [132] (ABNORMALITY [LOW LEVEL] IN ACCELERATOR SENSOR SYSTEM) 856

EA-14 ERROR CODE [135] (ABNORMALITY [HIGH LEVEL] IN OIL PRESSURE SENSOR SYSTEM) 857

EA-15 ERROR CODE [141] (ABNORMALITY [LOW LEVEL] IN OIL PRESSURE SENSOR SYSTEM) 858

EA-16 ERROR CODE [143] (ABNORMAL DROP IN OIL PRESSURE (LEVEL 1)) 859

EA-17 ERROR CODE [144] (ABNORMALITY [HIGH LEVEL] IN WATER TEMPERATURE SENSOR SYSTEM) 860

EA-18 ERROR CODE [145] (ABNORMALITY [LOW LEVEL] IN WATER TEMPERATURE SENSOR SYSTEM) 861

EA-19 ERROR CODE [151] (ABNORMAL RISE IN WATER TEMPERATURE) 861

EA-20 ERROR CODE [153] (ABNORMALITY [HIGH LEVEL] IN INTAKE AIR TEMPERATURE SENSOR SYSTEM) 862

EA-21 ERROR CODE [154] (ABNORMALITY [LOW LEVEL] IN INTAKE AIR TEMPERATURE SENSOR SYSTEM) 862

EA-22 ERROR CODE [221] (ABNORMALITY [HIGH LEVEL] IN ATMOSPHERIC PRESSURE SENSOR SYSTEM) 863

EA-23 ERROR CODE [222] (ABNORMALITY [LOW LEVEL] IN ATMOSPHERIC PRESSURE SENSOR SYSTEM) 864

EA-24 ERROR CODE [234] (OVERSPEED) 866

EA-25 ERROR CODE [254] (ABNORMALITY IN FUEL SHUT-OFF VALVE SYSTEM VOLTAGE) 867

EA-26 ERROR CODE [259] (ABNORMALITY IN FUEL SHUT-OFF VALVE) 868

EA-27 ERROR CODE [261] (ABNORMAL RISE IN FUEL TEMPERATURE) 868

EA-28 ERROR CODE [263] (ABNORMALITY [HIGH LEVEL] IN FUEL TEMPERATURE SENSOR SYSTEM) 869

EA-29 ERROR CODE [265] (ABNORMALITY [LOW LEVEL] IN FUEL TEMPERATURE SENSOR SYSTEM) 869

EA-30 ERROR CODE [316] (ABNORMALITY IN FUEL PUMP ACTUATOR SYSTEM CURRENT) 870

EA-31 ERROR CODE [318] (ABNORMALITY IN FUEL PUMP ACTUATOR) 871

EA-32 ERROR CODE [343] (ABNORMALITY IN CONTROLLER INTERNAL COMMUNICATION) 871

EA-33 ERROR CODE [346] (ABNORMALITY IN CONTROLLER POWER DOWN) 872

EA-34 ERROR CODE [384] (ABNORMALITY IN PREHEATING HEATER CONTROL SYSTEM) 873

EA-35 ERROR CODE [415] (ABNORMAL DROP IN OIL PRESSURE (LEVEL 2)) 874

EA-36 ERROR CODE [423] (ABNORMALITY [IN RANGE] IN TIMING RAIL PRESSURE SENSOR SYSTEM) 874

EA-37 ERROR CODE [431] (ABNORMALITY [1] IN IDLING VALIDATION SWITCH SYSTEM) 876

EA-38 ERROR CODE [432] (IDLING VALIDATION PROCESS ERROR) 878

EA-39 ERROR CODE [441] (ABNORMALITY [LOW LEVEL] IN BATTERY VOLTAGE) 880

EA-40 ERROR CODE [442] (ABNORMALITY [HIGH LEVEL] IN BATTERY VOLTAGE) 880

EA-41 ERROR CODE [451] (ABNORMALITY [HIGH LEVEL] IN FUEL RAIL PRESSURE SENSOR SYSTEM) 881

EA-42 ERROR CODE [452] (ABNORMALITY [LOW LEVEL] IN FUEL RAIL PRESSURE SENSOR SYSTEM) 882

EA-43 ERROR CODE [455] (ABNORMALITY IN FUEL RAIL ACTUATOR SYSTEM CURRENT) 883

EA-44 ERROR CODE [467] (ABNORMALITY IN TIMING RAIL ACTUATOR CONTROL) 884

EA-45 ERROR CODE [468] (ABNORMALITY IN FUEL RAIL ACTUATOR CONTROL) 884

EA-46 ERROR CODE [514] (ABNORMALITY IN FUEL RAIL ACTUATOR) 884

EA-47 ERROR CODE [527] (ABNORMALITY IN DUAL OUTPUT SOLENOID A SYSTEM) 885

EA-48 ERROR CODE [551] (ABNORMALITY [2] IN IDLING VALIDATION SWITCH SYSTEM) 885

EA-49 ERROR CODE [554] (ABNORMALITY [IN RANGE] IN FUEL RAIL PRESSURE SENSOR) 886

TROUBLESHOOTING OF VHMS CONTROLLER SYSTEM (VHMS MODE) 889

ELECTRICAL SYSTEM DIAGRAM RELATED VHMS CONTROLLER 892

INFORMATION GIVEN IN TROUBLESHOOTING CHART 894

PHENOMENON TYPE CODE LIST 895

[DBB0KK] (OR VHMS_LED INDICATES [N901]) ABNORMALITY IN SOURCE VOLTAGE 896

[DBB5KP] (OR VHMS_LED INDICATES [N904]) ABNORMALITY IN SENSOR POWER SOURCE (5 V) SYSTEM 898

[DBB6KP] (OR VHMS_LED INDICATES [N902]) ABNORMALITY IN SENSOR POWER SOURCE (24 V) SYSTEM 900

[DBBRKR] (OR VHMS_LED DISPLAYS [N801]) DEFECTIVE CAN COMMUNICATIONS: DEFECTIVE COMMUNICATIONS (KR) (BETWEEN ENGINE CONTROLLER AND VHMS CONTROLLER) 902

[DGE1KB] (OR VHMS_LED DISPLAYS [N242]) DISCONNECTION, SHORT CIRCUIT WITH CHASSIS GROUND IN ENGINE OIL TEMPERATURE SENSOR SYSTEM (KB) {30 MIN (AT 500 RPM OR ABOVE) AFTER STARTING ENGINE} 904

[DGE1KY] (OR VHMS_LED DISPLAYS [N242]) SHORT CIRCUIT WITH POWER SOURCE (HOT SHORT) IN ENGINE OIL TEMPERATURE SENSOR SYSTEM (KY) 905

[DGE5KX] (OR VHMS_LED DISPLAYS [N401]) FAILURE IN AMBIENT TEMPERATURE SENSOR SYSTEM: INPUT SIGNAL OUTSIDE RANGE (KX) 906

[DGT4KA] (OR VHMS_LED DISPLAYS [N312]) DISCONNECTION, SHORT CIRCUIT WITH CHASSIS GROUND IN NO 1, 2, 3 (FRONT) EXHAUST TEMPERATURE SENSOR SYSTEM (KA) 908

[DGT4KB] (OR VHMS_LED DISPLAYS [N311]) SHORT CIRCUIT WITH POWER SOURCE (HOT SHORT) IN NO 1, 2, 3 (REAR) EXHAUST TEMPERATURE SENSOR SYSTEM (KB) 910

[DGT5KA] (OR VHMS_LED DISPLAYS [N322]) DISCONNECTION, SHORT CIRCUIT WITH CHASSIS GROUND IN NO 4, 5, 6 (FRONT) EXHAUST TEMPERATURE SENSOR SYSTEM (KA) 912

[DGT5KB] (OR VHMS_LED DISPLAYS [N321]) SHORT CIRCUIT WITH POWER SOURCE (HOT SHORT) IN NO 4, 5, 6 (FRONT) EXHAUST TEMPERATURE SENSOR SYSTEM (KB) 914

[DHE5KB] (OR VHMS_LED DISPLAYS [N332]) DISCONNECTION, SHORT CIRCUIT WITH CHASSIS GROUND IN ENGINE BLOW-BY PRESSURE SENSOR SYSTEM (KA) 916

[DHE5KY] (OR VHMS_LED DISPLAYS [N331]) SHORT CIRCUIT WITH POWER SOURCE (HOT SHORT) IN ENGINE BLOW-BY PRESSURE SENSOR SYSTEM (KY) 918

[DHT3KX] (OR VHMS_LED DISPLAYS [N614]) TROUBLE IN TRANSMISSION OIL PRESSURE SENSOR SYSTEM: OUT OF INPUT SIGNAL RANGE (KX) 920

[DHP2KX] (OR VHMS_LED DISPLAYS [N531]) TROUBLE IN MAIN PUMP OIL PRESSURE SENSOR SYSTEM: OUT OF INPUT SIGNAL RANGE (KX) 922

[DHT8KX] (OR VHMS_LED DISPLAYS [N533]) TROUBLE IN STEERING OIL PRESSURE SENSOR SYSTEM: OUT OF INPUT SIGNAL RANGE (KX) 924

[DGH2KX] (OR VHMS_LED DISPLAYS [N537]) TROUBLE IN HYDRAULIC OIL TEMPERATURE SENSOR SYSTEM: OUT OF INPUT SIGNAL RANGE (KX) 926

[DHU2KX] (OR VHMS_LED DISPLAYS [N711]) TROUBLE IN FRONT BRAKE OIL PRESSURE SENSOR SYSTEM: OUT OF INPUT SIGNAL RANGE (KX) 928

[DHU3KX] (OR VHMS_LED DISPLAYS [N712]) TROUBLE IN REAR BRAKE OIL PRESSURE SENSOR SYSTEM: OUT OF INPUT SIGNAL RANGE (KX) 930

[DGR4KX] (OR VHMS_LED DISPLAYS [N717]) TROUBLE IN FRONT BRAKE OIL TEMPERATURE SENSOR SYSTEM: OUT OF INPUT SIGNAL RANGE (KX) 932

[F@BBZL] (OR VHMS_LED DISPLAYS [N338]) ENGINE BLOW-BY PRESSURE IS HIGH: (ZL) 933

[F@BYNR] (OR VHMS_LED DISPLAYS [N362]) NO 1, 2, 3 (REAR) EXHAUST TEMPERATURE IS HIGH (2): (NR) 934

[F@BYNS] (OR VHMS_LED DISPLAYS [N361]) NO 1, 2, 3 (REAR) EXHAUST TEMPERATURE IS HIGH (1): (NS) 935

[F@BZNR] (OR VHMS_LED DISPLAYS [N372]) NO 4, 5, 6 (FRONT) EXHAUST TEMPERATURE IS HIGH (2): (NR) 936

[F@BZNS] (OR VHMS_LED DISPLAYS [N371]) NO 4, 5, 6 (FRONT) EXHAUST TEMPERATURE IS HIGH (1): (NS) 937

VHMS-1 ABNORMALITY IN SATELLITE DATA COMMUNICATION 938

a) SATELLITE COMMUNICATION DATA ARE NOT TRANSMITTED 938

b) ABNORMALITY IN DOWNLOADING INTO PC OR SETTING OF PC 942

VHMS-2 ABNORMALITY IN SAVING DATA IN VHMS CONTROLLER (DATA ARE NOT SAVED) 944

VHMS-3 ENGINE BLOW-BY PRESSURE INDICATED BY MONITOR IS LOW (WHEN BLOW-BY PRESSURE MEASURED WITH MEASURING INSTRUMENT IS NORMAL) 946

30 DISASSEMBLY AND ASSEMBLY 947

METHOD OF USING MANUAL 951

PRECAUTIONS WHEN CARRYING OUT OPERATION 953

SPECIAL TOOLS LIST 956

SKETCHES OF SPECIAL TOOLS 962

REMOVAL OF STARTING MOTOR ASSEMBLY 966

INSTALLATION OF STARTING MOTOR 966

REMOVAL OF ALTERNATOR ASSEMBLY (SERIAL NO : 50001 – 51000) 967

INSTALLATION OF ALTERNATOR ASSEMBLY (SERIAL NO : 50001 – 51000) 967

REMOVAL OF ALTERNATOR ASSEMBLY (SERIAL NO : 51001 AND UP) 968

INSTALLATION OF ALTERNATOR ASSEMBLY (SERIAL NO : 51001 AND UP) 968

REMOVAL OF ENGINE OIL COOLER ASSEMBLY (SERIAL NO : 50001 – 51000) 970

INSTALLATION OF ENGINE OIL COOLER ASSEMBLY (SERIAL NO : 50001 – 51000) 970

REMOVAL OF ENGINE OIL COOLER ASSEMBLY (SERIAL NO : 51001 AND UP) 971

INSTALLATION OF ENGINE OIL COOLER ASSEMBLY (SERIAL NO : 51001 AND UP) 971

REMOVAL OF FUEL INJECTION PUMP ASSEMBLY 973

INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY 974

REMOVAL OF WATER PUMP ASSEMBLY 975

INSTALLATION OF WATER PUMP ASSEMBLY 975

REMOVAL OF NOZZLE HOLDER ASSEMBLY 976

INSTALLATION OF NOZZLE HOLDER ASSEMBLY 976

REMOVAL OF TURBOCHARGER ASSEMBLIES 977

INSTALLATION OF TURBOCHARGER ASSEMBLY 978

REMOVAL OF ENGINE FRONT SEAL 979

REPLACEMENT OF ENGINE REAR SEAL 981

REMOVAL OF CYLINDER HEAD 983

INSTALLATION OF CYLINDER HEAD ASSEMBLY 986

REMOVAL OF THERMOSTAT ASSEMBLY 988

INSTALLATION OF THERMOSTAT ASSEMBLY 988

REMOVAL OF HYDRAULIC OIL COOLER, RADIATOR, AFTERCOOLER ASSEMBLY 989

INSTALLATION OF HYDRAULIC OIL COOLER, RADIATOR, AFTERCOOLER ASSEMBLY 990

REMOVAL OF HYDRAULIC OIL COOLER, RADIATOR, AFTERCOOLER, FUEL COOLER ASSEMBLY 991

INSTALLATION OF HYDRAULIC OIL COOLER, RADIATOR, AFTERCOOLER, FUEL COOLER ASSEMBLY 993

REMOVAL OF ENGINE, DAMPER ASSEMBLY (SERIAL NO : 50001 – 51000) 995

INSTALLATION OF ENGINE, DAMPER ASSEMBLY (SERIAL NO : 50001 – 51000) 997

REMOVAL OF ENGINE, DAMPER ASSEMBLY (SERIAL NO : 51001 AND UP) 998

INSTALLATION OF ENGINE, DAMPER ASSEMBLY (SERIAL NO : 51001 AND UP) 1000

REMOVAL OF DAMPER 1002

INSTALLATION OF DAMPER ASSEMBLY 1002

DISASSEMBLY OF DAMPER 1003

ASSEMBLY OF DAMPER 1005

DISASSEMBLY OF PTO ASSEMBLY 1009

ASSEMBLY OF PTO ASSEMBLY 1011

REMOVAL OF TORQUE CONVERTER, TRANSMISSION ASSEMBLY 1014

INSTALLATION OF TORQUE CONVERTER, TRANSMISSION ASSEMBLY 1018

DISASSEMBLY OF TORQUE CONVERTER ASSEMBLY 1019

ASSEMBLY OF TORQUE CONVERTER ASSEMBLY 1023

DISASSEMBLY OF TRANSMISSION ASSEMBLY 1028

ASSEMBLY OF TRANSMISSION 1042

REMOVAL OF TRANSMISSION VALVE ASSEMBLY 1057

INSTALLATION OF TRANSMISSION VALVE ASSEMBLY 1057

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION CONTROL VALVE 1058

DISASSEMBLY OF TRANSFER ASSEMBLY 1063

ASSEMBLY OF TRANSFER ASSEMBLY 1070

REMOVAL OF CENTER SUPPORT ASSEMBLY 1079

INSTALLATION OF CENTER SUPPORT 1080

DISASSEMBLY OF CENTER SUPPORT 1081

ASSEMBLY OF CENTER SUPPORT 1083

DISASSEMBLY OF DRIVE SHAFT 1086

ASSEMBLY OF DRIVE SHAFT 1088

REMOVAL OF FRONT AXLE 1090

INSTALLATION OF FRONT AXLE ASSEMBLY 1091

REMOVAL OF FRONT DIFFERENTIAL ASSEMBLY (SERIAL NO : 50001 – 50044) 1092

INSTALLATION OF FRONT DIFFERENTIAL ASSEMBLY (SERIAL NO : 50001 – 50044) 1093

REMOVAL OF FRONT DIFFERENTIAL ASSEMBLY (SERIAL NO : 50045 AND UP) 1094

INSTALLATION OF FRONT DIFFERENTIAL ASSEMBLY (SERIAL NO : 50045 AND UP) 1095

REMOVAL OF REAR AXLE ASSEMBLY 1096

INSTALLATION OF REAR AXLE ASSEMBLY 1100

REMOVAL OF REAR DIFFERENTIAL ASSEMBLY 1101

INSTALLATION OF REAR DIFFERENTIAL ASSEMBLY 1102

DISASSEMBLY OF DIFFERENTIAL ASSEMBLY 1103

ASSEMBLY OF DIFFERENTIAL ASSEMBLY 1107

DISASSEMBLY OF FINAL DRIVE 1116

ASSEMBLY OF FINAL DRIVE 1120

REMOVAL OF ORBIT ROLL ASSEMBLY 1126

INSTALLATION OF ORBIT ROLL ASSEMBLY 1126

REMOVAL OF STEERING CYLINDER ASSEMBLY 1127

INSTALLATION OF STEERING CYLINDER ASSEMBLY 1129

REMOVAL OF STEERING DEMAND VALVE ASSEMBLY 1130

INSTALLATION OF STEERING DEMAND VALVE ASSEMBLY 1131

REMOVAL OF BRAKE VALVE ASSEMBIES 1132

INSTALLATION OF BRAKE VALVE ASSEMBLY 1132

DISASSEMBLY OF BRAKE VALVE (RIGHT) 1133

ASSEMBLY OF BRAKE VALVE (RIGHT) 1135

DISASSEMBLY OF BRAKE VALVE (LEFT) 1137

ASSEMBLY OF BRAKE VALVE (LEFT) 1139

REMOVAL OF SLACK ADJUSTER ASSEMBLY 1141

INSTALLATION OF SLACK ADJUSTER ASSEMBLY 1141

DISASSEMBLY OF SLACK ADJUSTER 1142

ASSEMBLY OF SLACK ADJUSTER 1143

REMOVAL OF BRAKE ASSEMBLY 1144

INSTALLATION OF BRAKE ASSEMBLY 1145

DISASSEMBLY OF BRAKE ASSEMBLY 1146

ASSEMBLY OF BRAKE ASSEMBLY 1150

REMOVAL OF HYDRAULIC PUMP 1156

INSTALLATION OF HYDRAULIC PUMP ASSEMBLY 1157

DISASSEMBLY OF PISTON PUMP ASSEMBLY 1158

ASSEMBLY OF PISTON PUMP ASSEMBLY 1164

REMOVAL OF HYDRAULIC TANK ASSEMBLY 1180

INSTALLATION OF HYDRAULIC TANK 1181

REMOVAL OF PPC VALVE 1182

INSTALLATION OF PPC VALVE 1183

DISASSEMBLY OF PPC VALVE 1184

ASSEMBLY OF PPC VALVE 1184

REMOVAL OF WORK EQUIPMENT VALVE ASSEMBLY 1185

INSTALLATION OF WORK EQUIPMENT VALVE ASSEMBLY 1186

DISASSEMBLY OF WORK EQUIPMENT CONTROL VALVE 1187

ASSEMBLY OF WORK EQUIPMENT CONTROL VALVE 1189

REMOVAL OF DUMP CYLINDER 1191

INSTALLATION OF DUMP CYLINDER 1191

REMOVAL OF LIFT CYLINDER 1192

INSTALLATION OF LIFT CYLINDER 1193

DISASSEMBLY OF STEERING, LIFT, DUMP CYLINDER 1194

ASSEMBLY STEERING, LIFT, DUMP CYLINDER 1196

REMOVAL OF CENTER HINGE PIN 1198

INSTALLATION OF CENTER HINGE PIN 1204

REMOVAL OF WORK EQUIPMENT ASSEMBLY 1208

INSTALLATION OF WORK EQUIPMENT ASSEMBLY 1211

REMOVAL OF BULKHEAD ASSEMBLY (SERIAL NO : 50001 – 51000) 1213

INSTALLATION OF BULKHEAD ASSEMBLY (SERIAL NO : 50001 – 51000) 1214

REMOVAL OF BULKHEAD ASSEMBLY (SERIAL NO : 51001 AND UP) 1215

INSTALLATION OF BULKHEAD ASSEMBLY (SERIAL NO : 51001 AND UP) 1217

REMOVAL OF FLOOR FRAME ASSEMBLY 1219

INSTALLATION OF FLOOR FRAME ASSEMBLY 1222

REMOVAL OF COUNTERWEIGHT 1224

INSTALLATION OF COUNTERWEIGHT 1224

REMOVAL OF FUEL TANK ASSEMBLY (SERIAL NO : 50001 – 51000) 1225

INSTALLATION OF FUEL TANK ASSEMBLY (SERIAL NO : 50001 – 51000) 1226

REMOVAL OF FUEL TANK ASSEMBLY (SERIAL NO : 51001 AND UP) 1227

INSTALLATION OF FUEL TANK ASSEMBLY (SERIAL NO : 51001 AND UP) 1228

REMOVAL OF CAB 1229

INSTALLATION OF CAB 1231

REMOVAL OF STOP VALVE ASSEMBLY 1232

INSTALLATION OF STOP VALVE ASSEMBLY 1232

REMOVAL OF ACCUMULATOR CHARGE VALVE ASSEMBLY 1233

INSTALLATION OF ACCUMULATOR CHARGE VALVE ASSEMBLY 1233

DISASSEMBLY OF ACCUMULATOR CHARGE VALVE 1234

ASSEMBLY OF ACCUMULATOR CHARGE VALVE 1235

REMOVAL OF PARKING BRAKE SOLENOID VALVE AND PRESSURE SWITCH ASSEMBLY 1237

INSTALLATION OF PARKING BRAKE SOLENOID VALVE AND PRESSURE SWITCH ASSEMBLY 1237

REMOVAL OF DIVERTER VALVE ASSEMBLY 1238

INSTALLATION OF DIVERTER VALVE ASSEMBLY 1238

DISASSEMBLY OF DIVERTER VALVE 1239

ASSEMBLY OF DIVERTER VALVE 1240

REMOVAL OF EMERGENCY STEERING PUMP ASSEMBLY 1242

INSTALLATION OF EMERGENCY STEERING PUMP ASSEMBLY 1242

REMOVAL OF PARKING BRAKE ASSEMBLY 1243

INSTALLATION OF PARKING BRAKE ASSEMBLY 1244

DISASSEMBLY OF PARKING BRAKE CALIPERS 1246

ASSEMBLY OF PARKING BRAKE CALIPERS 1248

REMOVAL OF PARKING BRAKE PAD (SERIAL NO : 50001 – 50044) 1250

INSTALLATION PARKING BRAKE PAD (SERIAL NO : 50001 – 50044) 1250

REMOVAL OF PARKING BRAKE PAD (SERIAL NO : 50045 AND UP) 1251

INSTALLATION PARKING BRAKE PAD (SERIAL NO : 50045 AND UP) 1252

REMOVAL OF REAR TIRE ASSEMBLY 1253

INSTALLATION OF REAR TIRE ASSEMBLY 1253

REMOVAL OF AIR CONDITIONER COMPRESSOR ASSEMBLY (SERIAL NO : 50001 – 51000) 1254

INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY (SERIAL NO : 50001 – 51000) 1255

REMOVAL OF AIR CONDITIONER COMPRESSOR ASSEMBLY (SERIAL NO : 51001 AND UP) 1256

INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY (SERIAL NO : 51001 AND UP) 1256

REMOVAL OF AIR CONDITIONER CONDENSER ASSEMBLIES 1257

INSTALLATION OF AIR CONDITIONER CONDENSER ASSEMBLY 1258

REMOVAL OF RECEIVER TANK ASSEMBLY 1260

INSTALLATION OF RECEIVER TANK ASSEMBLY 1260

REMOVAL OF AIR CONDITIONER UNIT ASSEMBLY 1261

INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY 1262

REMOVAL OF MAIN MONITOR 1263

INSTALLATION OF MAIN MONITOR 1264

REMOVAL OF MAINTENANCE MONITOR ASSEMBLY 1265

INSTALLATION OF MAINTENANCE MONITOR ASSEMBLY 1265

REMOVAL OF ENGINE, APS CONTROLLER ASSEMBLY 1266

INSTALLATION OF ENGINE, APS CONTROLLER ASSEMBLY 1266

REMOVAL OF AJSS LEVER SWITCH ASSEMBLY 1267

INSTALLATION OF AJSS LEVER SWITCH ASSEMBLY 1270

40 MAINTENANCE STANDARD 1275

ENGINE AND TANSMISSION MOUNT 1277

DAMPER 1278

TORQUE CONVERTER AND PTO 1280

TORQUE CONVERTER REGULATOR VALVE 1281

TRANSMISSION 1282

TRANSMISSION CONTROL VALVE 1286

TRANSFER 1292

DRIVE SHAFT 1294

CENTER SUPPORT 1295

DIFFERENTIAL 1296

FINAL DRIVE 1298

AXLE MOUNT 1300

CENTER HINGE PIN 1302

STEERING COLUMN 1304

STEERING DEMAND VALVE 1306

DIVERTER VALVE 1308

STEERING CYLINDER MOUNT 1309

EMERGENCY STEERING PUMP 1310

BRAKE VALVE 1312

SLACK ADJUSTER 1319

BRAKE 1320

PARKING BRAKE 1324

CONTROL PUMP 1325

STEERING AND SWITCH PUMP 1326

MAIN PISTON PUMP 1327

MAIN CONTROL VALVE 1328

PPC VALVE 1332

PPC RELIEF VALVE 1334

HYDRAULIC CYLINDER 1335

WORK EQUIPMENT LINKAGE 1336

BUCKET 1338

BUCKET POSITIONER AND BOOM KICK-OUT 1339

90 OTHERS 1341

ELECTRIC CIRCUIT DIAGRAM (1/5) (SERIAL NO : 50001 – 51000) 1343

ELECTRIC CIRCUIT DIAGRAM (2/5) (SERIAL NO : 50001 – 51000) 1345

ELECTRIC CIRCUIT DIAGRAM (3/5) (SERIAL NO : 50001 – 51000) 1347

ELECTRIC CIRCUIT DIAGRAM (4/5) (SERIAL NO : 50001 – 51000) 1349

ELECTRIC CIRCUIT DIAGRAM (5/5) (SERIAL NO : 50001 – 51000) 1351

ELECTRIC CIRCUIT DIAGRAM (1/6) (SERIAL NO : 51001 AND UP) 1353

ELECTRIC CIRCUIT DIAGRAM (2/6) (SERIAL NO : 51001 AND UP) 1355

ELECTRIC CIRCUIT DIAGRAM (3/6) (SERIAL NO : 51001 AND UP) 1357

ELECTRIC CIRCUIT DIAGRAM (4/6) (SERIAL NO : 51001 AND UP) 1359

ELECTRIC CIRCUIT DIAGRAM (5/6) (SERIAL NO : 51001 AND UP) 1361

ELECTRIC CIRCUIT DIAGRAM (6/6) (SERIAL NO : 51001 AND UP) 1363

ELECTRIC CIRCUIT DIAGRAM (1/3) (WITH AUTO SHIFT AND JOYSTICK STEERING) (SERIAL NO : 50001 – 51000) 1365

ELECTRIC CIRCUIT DIAGRAM (2/3) (WITH AUTO SHIFT AND JOYSTICK STEERING) (SERIAL NO : 50001 – 51000) 1367

ELECTRIC CIRCUIT DIAGRAM (3/3) (WITH AUTO SHIFT AND JOYSTICK STEERING) (SERIAL NO : 50001 – 51000) 1369

ELECTRIC CIRCUIT DIAGRAM (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) (1/3) (SERIAL NO : 51001 AND UP) 1371

ELECTRIC CIRCUIT DIAGRAM (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) (2/3) (SERIAL NO : 51001 AND UP) 1373

ELECTRIC CIRCUIT DIAGRAM (AJSS (ADVANCED JOYSTICK STEERING SYSTEM) SPECIFICATION) (3/3) (SERIAL NO : 51001 AND UP) 1375

ELECTRIC CIRCUIT DIAGRAM (AUTO-GREASING SPECIFICATION) 1377

IMAGES PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]

S.V